Project Description

AUTOMATIC PRESSURE STATIONS

The automatic pressure station is a device designed for the water pumping as well as keeping and increasing pressure in the pipelines. The automatic pressure station is used to ensure the required pressure in the pipeline of potable and supply water, water for firefighting purposes and other water.

TECHNICAL CHARACTERISTICS

The automatic pressure stations can be divided into two groups, depending of their equipment:

- automatic pressure stations with a big pressure tank equipped usually with one pump, sometimes with more pumps

- automatic pressure stations without any pressure tank or with a small pressure tank equipped with one or more pumps (2 – 6 pumps), with a frequency converter and a sophisticated control panel. A pressure gauge controls the defined pressure in the pipelines and in case of the pressure decrease, the control panel turns on the pumps and controls their run. The small pressure tank ensures more stable pressure during the short period until the pumps react to fast changes.

The automatic pressure station consists of a stainless frame, on which the pumps and other needed accessories are mounted. The pumps can work in different modes as set and needed. They are usually equipped with frequency converters. The pump control may be completed with a “soft starter” that ensures controlled pump start, decreases starting voltage and engine load and thus prolongs the life span of the engine and ensures more continuous flow in the pipelines.

The accessories of the automatic pressure station include plug valves, check valves, a pressure switch, a pressure gauge, a membrane pressure tank and a control panel.

The automatic pressure station is attached to the pipelines: to the intake and water delivery pipe made from stainless steel, cast iron or HDPE-material.

In fact, the control panel is a computer that manages the pumps run as required, evaluates the actual water needed in the system and defines, how many pumps are to run and with what optimal rotation speed. Due to the frequency converter by the consecutive water offtake, the first pump starts to run gradually and when it works with optimal efficiency, only then the next pump starts to run – such a control of the automatic pressure station ensures its optimal and effective run.

The control panel may be equipped with different modes that enable the distance control of the automatic pressure station (data remote transfer). By the means of different applications, it is possible to monitor the pump state at distance and define so an appropriate time for their service and maintenance.

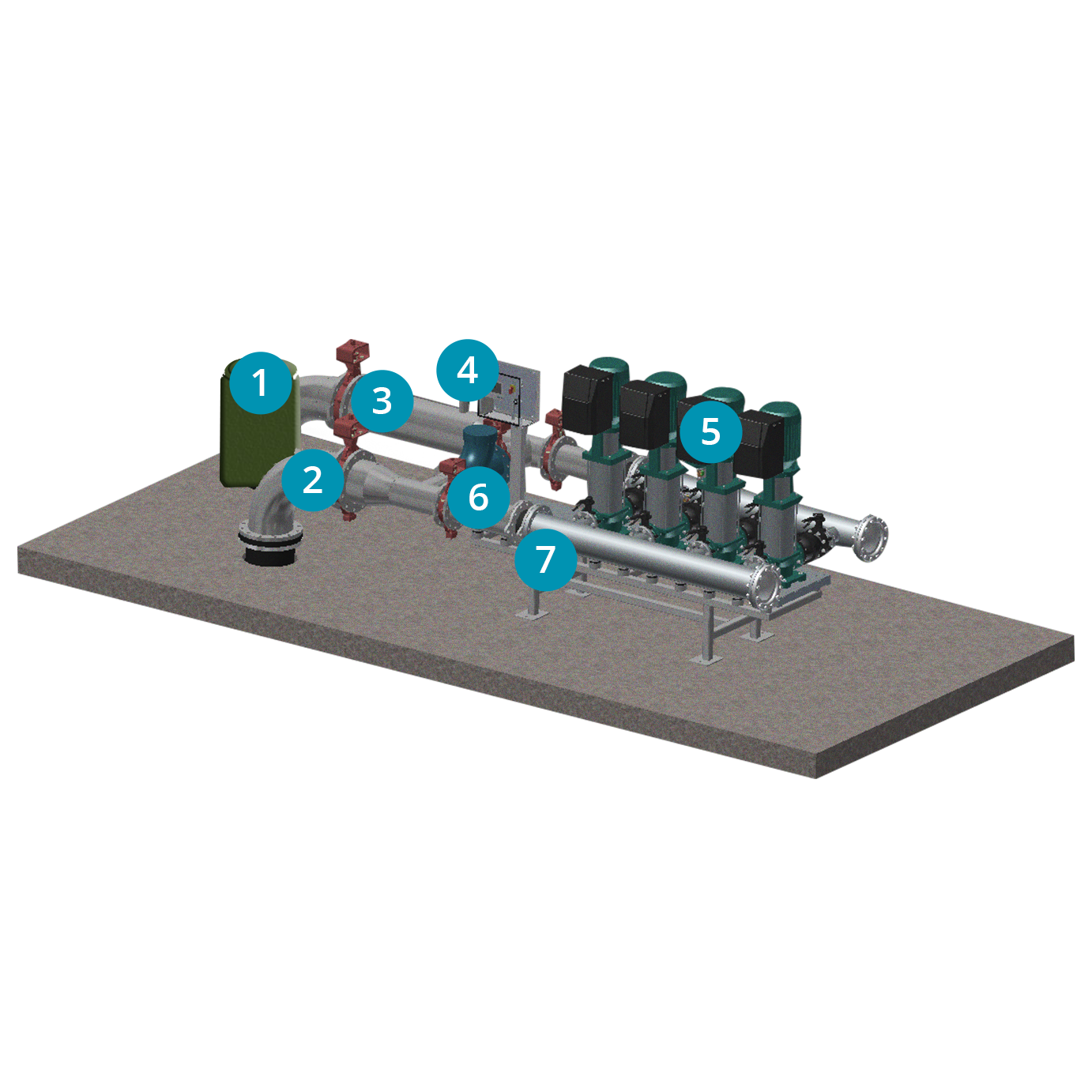

DESCRIPTION

1. Pressure Tank

2. Plug Valve

3. Stainless Pipe

4. Control Panel

5. Pump

6. Ball Check Valve

7. Rubber Expansion Joint